Crushing concrete is no longer the exclusive domain of heavy industry; it has become a cornerstone in modern construction cost-saving strategies. As concrete demolition and recycling surge globally, contractors, developers, and even municipalities are searching for the most economical way to handle massive volumes of debris. While concrete crushers for sale are often touted as the go-to machinery for this task, they are not the only players in the game. Many low-budget alternatives claim to offer similar outcomes at a fraction of the cost—but do they hold up under scrutiny?

This article dissects the cost-benefit dynamics of traditional concrete crushers compared to lesser-known yet increasingly popular alternatives. By interrogating their upfront costs, operational efficiencies, and long-term implications, this analysis seeks to answer one pressing question: what is truly the cheapest way to crush concrete ?

1. The True Cost of Concrete Crushers

Capital Expenditure vs Operational Savings

Concrete crushers—whether jaw, impact, or cone types—require significant capital investment. A mid-range mobile crusher can cost anywhere from $100,000 to $300,000. However, the allure lies in its throughput efficiency. A decent jaw crusher can process 50–100 tons per hour, and in larger models, even more. This volume significantly offsets the initial expense over time, especially on large-scale demolition or urban renewal projects.

Operational savings are also compelling. Many crushers feature fuel-efficient engines and automatic systems that minimize idle time. If managed correctly, their stone crusher price per ton can become impressively low— as little as $3 to $5 per ton . The caveat? You must already have the infrastructure to support such a machine, including skilled operators and maintenance routines.

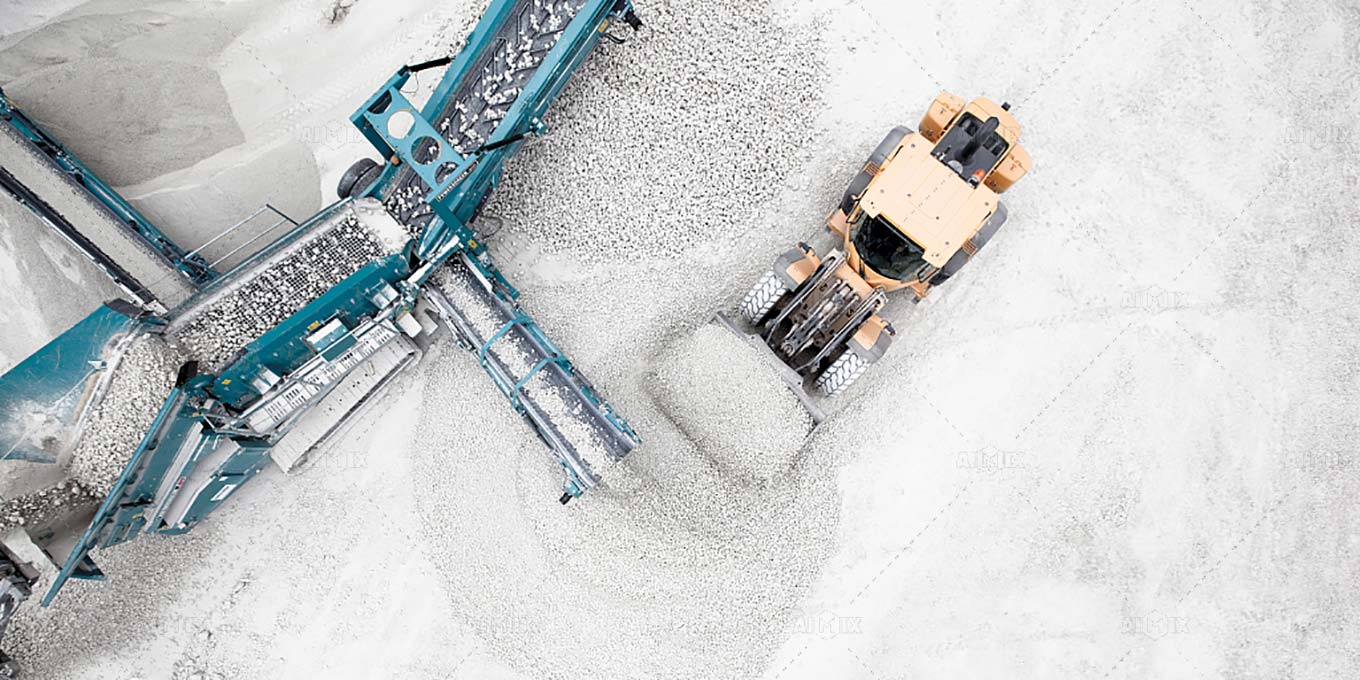

Portability and On-Site Processing

One underappreciated cost-saving feature of crushers is mobility. Modern tracked crushers can be deployed directly on-site, eliminating the need to transport material to a central crushing facility. This reduces not only fuel consumption and truck rental fees but also time lost in logistics. However, their weight and regulatory requirements can create legal and administrative hurdles in tightly controlled urban zones.

2. Viable Low-Cost Alternatives

Manual Labor and Sledgehammer Demolition

It might sound medieval, but for micro-scale jobs—think driveways, small patios, or garden slabs—the humble sledgehammer remains relevant. Labor-intensive and time-consuming, yes. But in developing regions or DIY scenarios, it’s unbeatable in affordability. The cost? Virtually nothing beyond labor. However, it lacks uniformity, efficiency, and safety assurance. Dust and inconsistent fragment sizes make it ill-suited for professional-grade aggregate reuse.

Skid Steer Attachments and Mini Crushers

Enter the hybrid middle-ground: compact crushing attachments for skid steers or mini-excavators. These mobile impact crushers typically cost between $10,000 and $30,000—a far cry from full-fledged crushers. Their throughput is modest (2–15 tons/hour), but sufficient for small-scale contractors or rural projects. Their main advantage is plug-and-play flexibility. Operators can leverage existing equipment without investing in a dedicated crushing plant.

These mini crushers offer cost-conscious contractors a functional compromise: mobility, acceptable throughput, and moderate capital outlay. However, the output quality can vary, and ongoing maintenance costs must not be underestimated.

3. Lifecycle Cost Comparison and Environmental Considerations

Cost per Ton Over Time

When evaluating the cheapest option, one must consider lifecycle cost—not just the sticker price. Full-size crushers shine when handling thousands of tons. Over time, their cost per ton dramatically decreases, making them the clear winner for sustained operations. Mini crushers, while cheaper upfront, have a higher cost per ton due to limited throughput and frequent wear part replacements.

Manual methods, though negligible in upfront investment, are not scalable and bear hidden labor and opportunity costs. In scenarios where time is money, they often fall short.

Sustainability and Waste Reutilization

Full-scale crushers generally produce more consistent recycled aggregate, suitable for high-spec concrete mixes and road sub-base. This enhances the potential for high-value reuse and environmental compliance. Manual methods and improvised solutions typically yield irregular fragments, limiting their application to low-grade fill or landfill cover—defeating the purpose of recycling.

Moreover, fuel-efficient modern crushers integrate dust suppression and emissions control systems, aligning with environmental standards. Such features may not seem directly cost-related but can significantly impact permitting and public perception—critical in today's ESG-driven world.